Cu sinter paste is expected to be utilized to replace conventional solder as a bonding material in power devices (power semiconductors).

Here we introduce Cu sinter paste in a three-part interview with Mr. Yamauchi, Technology and Development Group Leader in the AST Business Promotion Unit of the Business Creation Sector.

Although Mitsui Kinzoku does not yet have a commercial product, we understand that Cu sinter paste holds great potential. What type of material is it?

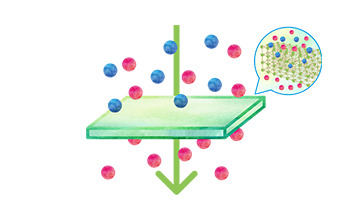

In simple terms, a mixture of metal particles and organic solvent. Slightly more pliable than clay, with a feeling somewhere between hand cream and mayonnaise, it is orange in color due to the copper inside. After a substrate has been printed with a layer of Cu sinter paste, electronic components and IC chips, etc. are placed on top. When heat and pressure are then applied, sintering occurs between the individual particles, and between the particles and the parts to be bonded. This bonds the parts to the substrate.

I think Cu sinter paste is maybe best understood by explaining how it is used. We anticipate that one of the applications for it will be in power devices (power semiconductors), which are semiconductors used to control electrical signals and electric power.

Power devices consist of semiconductors attached to a substrate, often using solder as a bonding material. High lead solder is used for applications that will be used in severe environments, such as for automotives. Since high lead solder responds flexibly when heated, it is still used, even when it is claimed that lead has been phased out, in Japan and elsewhere as an exception when reliability is particularly necessary. We believe that Cu sinter paste can replace this solder.

You have just mentioned sintering, what type of technique is this?

When the paste is heated, the organic solvent evaporates and the residual particles bind, or sinter, with each other. This sintering phenomenon is used as a technique to bind objects together—in the present case, the electronic components and the substrate. Among the various metals originally used in sintering, pastes based on silver and on copper both exist, but our development products use copper.

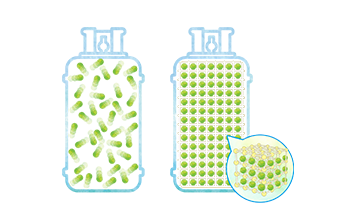

Two main bonding processes exist for sinter pastes. The first, just like for solder, involves printing the paste onto a substrate followed by heating in an oven. The other, pressure sintering, is an entirely new fabrication method in which, for example, heat is applied to a semiconductor chip while it is being compressed in a mold-like jig. The combination of heat and pressure enables pressure sintering to realize a densely sintered state thereby enhancing the reliability of the bonding. As thermal conductivity is also increased, pressure sintering is becoming established as the fabrication method for mass production with sinter pastes.

As one of the next generation semiconductors, silicon carbide facilitates the realization of higher functional power devices since it can operate under higher temperatures than conventional silicon semiconductors. However, when semiconductors are used at such temperatures the bonding solder cannot withstand the heat, either melting or losing its stability. In contrast, sinter pastes do not readily melt even at increased temperatures, so their reliability against heat can be expected.

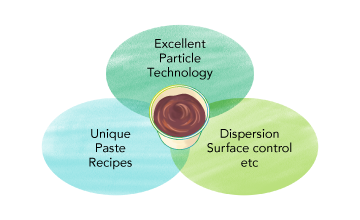

Sinter pastes based on silver are attracting much study. Although sintering is hampered by oxidation of metal surfaces, silver is an easy-to-use element in this regard due to its noble metal character. In contrast, counteracting the oxidation of Cu sinter paste is a difficult task. The care needed to avoid the natural oxidation of copper during storage is a major obstacle for copper paste development.

Sinter pastes are already being used for some devices. Flagship model, high function power devices using predominantly silver based sinter pastes are entering the market. There remains however a deep-seated desire to use copper to reduce cost.

[continued in Part 2]

Interviewee: Shinichi Yamauchi, Technology and Development Group Leader, AST Business Promotion Unit, Business Creation Sector, Mitsui Mining & Smelting Co., Ltd.

(Date of interview: February 21, 2023)

(The company is hereinafter referred to as "Mitsui Kinzoku.")