Against the background of increasing awareness of carbon neutrality as a global imperative, porous materials that create new possibilities for CO₂ separation/recovery technology development are drawing attention. Mitsui Kinzoku has formed a team of researchers with technical knowledge and experience in this field to develop a compact system for the effective implementation of CO₂ adsorbents, with a particular view to solving previous problems and encouraging smaller companies to introduce the adsorbent-based CO₂ separation/recovery technology.

Mitsui Kinzoku has developed porous materials that can support CO₂ separation and recovery processes as part of technology development efforts related to carbon neutrality. Would you give us some background on the related situation?

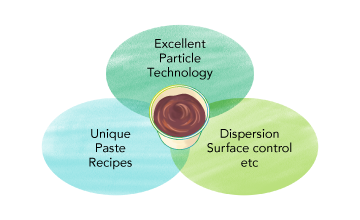

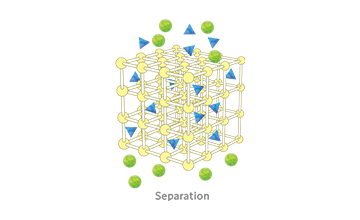

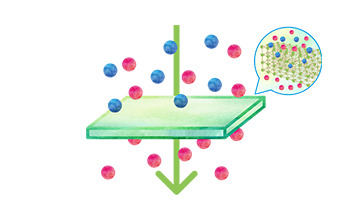

One of the purposes of our R&D Center is to create new businesses and we develop new materials and explore new applications accordingly. As part of our new materials development efforts, we have promoted research activities with a particular focus on porous materials as a core material of catalysts and adsorbents. Porous materials have a structure that is characterized by a myriad of fine pores, giving them a high specific surface area. Commonly known porous materials include zeolite, mesoporous silica, and metal-organic framework (MOF).

Among the various types of porous materials, this one caught our attention for its continuous macropore structure, which indicates a strong potential for a gas diffusion effect. In addition to CO₂ separation/recovery, we have also promoted the development of this material with an eye to application to catalyst supports. But rather than pursuing this direction, we have decided to focus primarily on the CO₂ separation/recovery process in response to strong demand from customers, setting the development theme for this material as contributing to carbon neutrality.

One grave issue related to this material is the difficulty with high-volume synthesis due to its sensitive nature, which makes it prone to structural transition according to even subtle changes in synthesis conditions. We will work on the improvement of synthesis methods aimed at high-volume synthesis, seeking to overcome this challenge and expand the application potential, setting themes related to other fields.

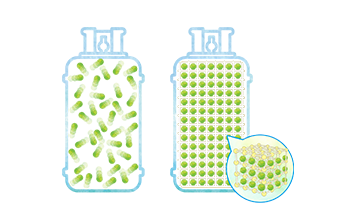

In the previous session, we touched on the plan to downsize CO₂ recovery devices by using this material. Does that plan aim to enable the introduction of planned devices to smaller factories, where it is difficult to adopt conventional devices because of their size?

For that issue, we are looking at distributed installation for smaller-scale facilities. Many large-scale facilities have introduced existing processes, such as those based on chemical absorption techniques, that have an adequate track record but are less suited for introduction to smaller facilities, which are typically characterized by low CO₂ levels, issues with availability of installation space and other practical hurdles and needs that differ from those of large facilities. Considering these circumstances, we are planning to create compact devices that can be installed even in small spaces, with scale-up options to be offered. Major future plans include providing functions for converting recovered CO₂ into valuable resources, such as fuel for on-site consumption, in addition to CO₂ separation/recovery capabilities.

Would you tell us something about the background behind the decision on the development of CO₂ separation/recovery technology using porous materials?

The Technology Group, an R&D function, is firmly committed to the principle of achieving a thorough understanding of the characteristics and functions of materials. According to this principle, we had comprehensive discussions with group members while exploring possible essential functions of materials for implementing efficient CO₂ separation/recovery processes. In the course of these discussions, we noted the possibility of applying various types of porous materials, characterized by variation in pore size, ranging from macropores to nanoscale pores, to innovate high-performance materials.

We promptly started to make prototypes and performed experimental demonstrations, which produced positive results supporting higher efficiency. We believe the recent achievement has resulted from efforts made by “taking full advantage of Material Intelligence,” as stated in our Corporate Slogan.

I understand many experienced professionals have contributed to the development of this technology. For the purpose of applying this material to the CO₂-related field, was Mitsui Kinzoku an early adapter to the relevant industry trend?

The development of porous materials as a core technology is one of our longtime technical subjects. On the back of this history, I think, we were able to act relatively quickly to launch a project to apply the materials to the CO₂-related field. In light of the risk of losing a good market entry opportunity due to mistimed actions, our susceptibility to the impact of government policies on carbon neutrality issues, and other factors, we understand the importance of acting with speed. We also recognize the need to cooperate with other companies in order to promote this business. So, going forward, we will form cooperative partnerships directed at the early implementation of developed processes.

(Date of interview: December 2, 2024)