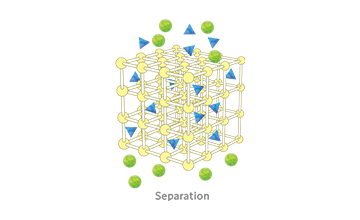

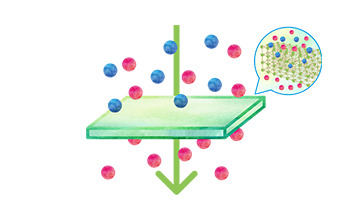

Mitsui Kinzoku has developed a CO₂ separation/recovery device that uses porous materials and has installed one at a Mitsui Kinzoku Group plant to start verification tests using actual exhaust gas. Seeking to expand the range of applications, the Company is pursuing the related technology with a view to taking carbon neutrality initiatives to a higher level while promoting the introduction of compact-type devices by smaller enterprises.

Mitsui Kinzoku started an experimental demonstration at a working plant to verify the performance of the new adsorbent it has developed as part of its carbon neutrality initiatives. The Company has reported positive results of the demonstration.

Upon completion of a compact-type CO₂ separation/recovery device, we installed a unit at the plant of Hachinohe Smelting Co., Ltd., a member of the Mitsui Kinzoku Group, in April 2024 and launched an experimental demonstration to verify the product’s CO₂ separation/recovery performance using real industrial fumes. In advance, a laboratory experiment was conducted at the R&D Center using mock gas with a composition similar to the exhaust gas generated by the plant to determine the operation conditions and recovery capacity before starting measurements at the plant using exhaust generated from actual operations. We obtained results indicating a recovery rate of approximately 90%, which was close to the level we had expected. In the societal context of aiming for carbon neutrality, this project looks to accommodate the issue of factories facing a need to reduce CO₂ emissions while having difficulty promoting electrification.

Experimental demonstration of the CO₂ recovery device launched at Hachinohe Smelting Co., Ltd.,

a subsidiary of Mitsui Kinzoku

The demonstration was launched after the laboratory experiment conducted at the R&D Center. Did you identify any unexpected issues from the demonstration in comparison with the laboratory experiment?

We faced many difficulties in transporting and setting up the device at the host plant, and had to negotiate with the plant repeatedly regarding the installation schedule, including preparations, taking into account the effect of seasonal factors on the related work. We sent a special team to the plant to carry out the demonstration, with machinery and equipment specialists included in case a problem occurred that needed technical support, as such support is not readily available at that location, unlike at the R&D Center. We will likely experience more and varied challenges as we move forward to perform assessments in different situations for the demonstration.

On top of this, we need to address issues posed by the periodical replacement of plant facilities, as this is accompanied by changes in the composition of the exhaust gas. The measurement analysis has actually indicated significant changes at greater-than-expected levels, presenting a striking contrast to the laboratory testing performed at the R&D Center under stable conditions.

Do you have any concrete plans for the future?

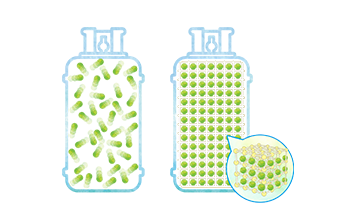

We are aiming for commercialization from around 2030 to 2035. Eyeing that, we will continue with our demonstration trials, mainly at Hachinohe Smelting Plant. We plan to scale up the device in three or so steps from the current offering, which is limited to the compact type.

What are some of the major issues to address in order to promote commercialization?

One of the most imperative issues is to establish the relevant technology. We will continue to work at Hachinohe Smelting Plant to this end, with the target year set at 2030. Other important issues are to respond to government policies and infrastructure building aimed at improving the environment for encouraging CO₂ emissions reduction efforts, chiefly by creating emissions regulations and subsidy programs. Anticipating that the situation will progress to provide an environment suitable for market entry around 2030, we will make appropriate preparations to seize favorable opportunities while facilitating development and demonstration efforts.

Toward 2030, the target year set for technology establishment and market entry, you will need to seek collaboration with other companies, right?

Right. CO₂ recovery serves no economic purpose when performed independently. To serve its purpose, it needs to be succeeded by other appropriate processes, like storing the recovered CO₂ underground or in concrete, or using it as fuel. We need to secure functions for performing these post-recovery processes, and creating appropriate regional and technical partnerships is essential for this. So we will work to build a value chain that can effectively use resources from smaller CO₂ emitters.

For the utilization of recovered CO₂, there are a number of processes that have already been put to practical use in areas like dry ice and soda manufacturing. Also, many large state-run facilities, such as power plants, are likely to pose difficulties related to the replacement of equipment. Given these circumstances, we are planning to start by targeting smaller CO₂ emitters that provide suitable environments for implementation of our device. More specifically, seeking the wide-scale adoption of our products, we will take advantage of our strengths to offer compact-size devices for sites that are not suited for existing techniques as well as capabilities for increasing the efficiency of CO₂ recovery and other functions directed at meeting the precise needs of smaller emitters.

Have you established technologies to manufacture porous materials for the CO₂ adsorbents to be commercialized?

We have already moved from laboratory trials to the bench-scale manufacturing stage. We are building a range of manufacturing technologies to be applied not only to CO₂ adsorbents but also many other product categories.

How would you describe the potential future outlook for porous materials?

We think of CO₂ recovery as one of many applications of porous materials. Additionally, we are facilitating the development of other possible applications in this area with an eye to commercialization, seeking to establish a new core business in this field.

Toward this end, we will step up our efforts to be able to launch new businesses to sell application products effectively while expanding our external networks to form appropriate partnerships.

Some people may wonder why Mitsui Kinzoku is promoting this kind of business. What’s behind it is our drive to achieve a thorough understanding of the characteristics and functions of materials, a business principle that guides the Technology Group of the Business Creation Sector. In line with this principle, we have built strong technical capabilities and advantages for the development of porous materials and are striving to expand the range of applications for them, rather than focusing only on offering CO₂-related solutions because we do not view that as the only end goal. By promoting these capabilities and advantages, we hope to increase the user base of our products and also to amplify our industrial presence so that customers will choose us as a strong partner in seeking good solutions to their issues.

(Date of interview: December 2, 2024)