- Features

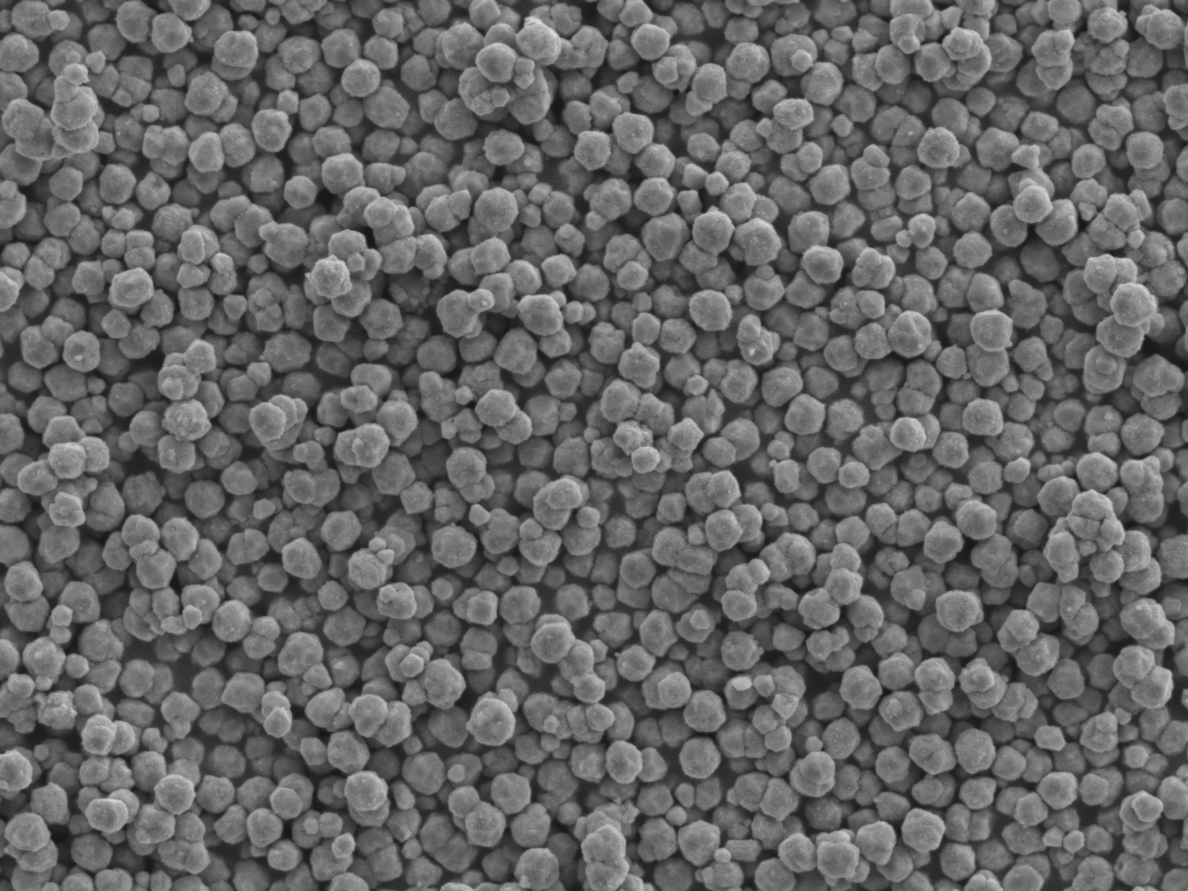

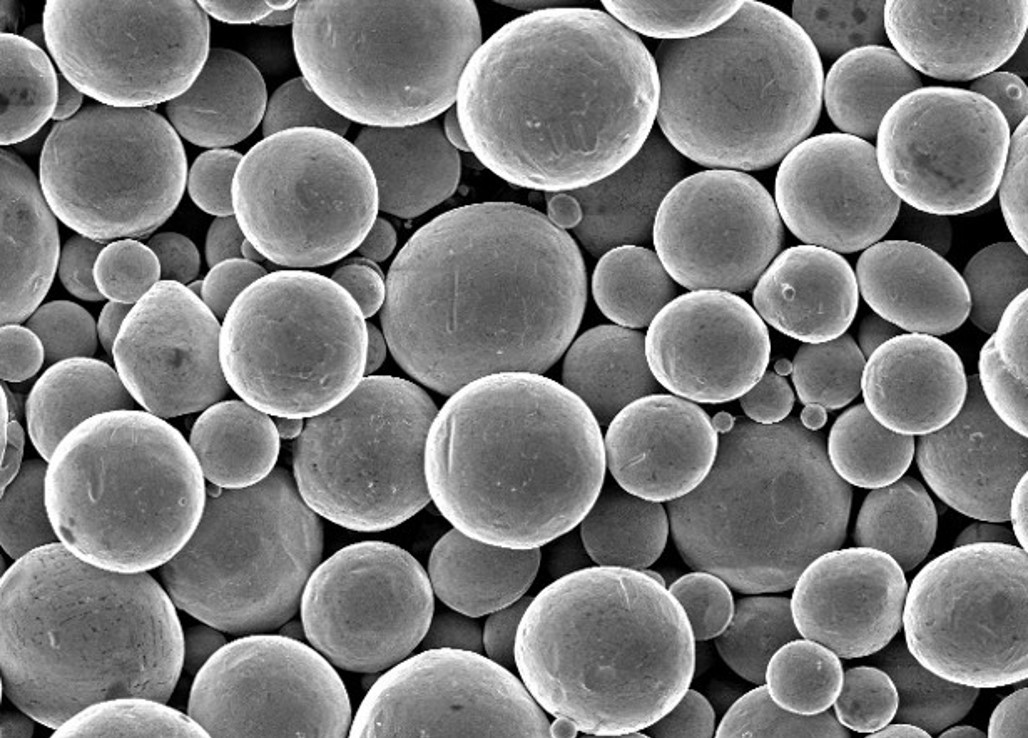

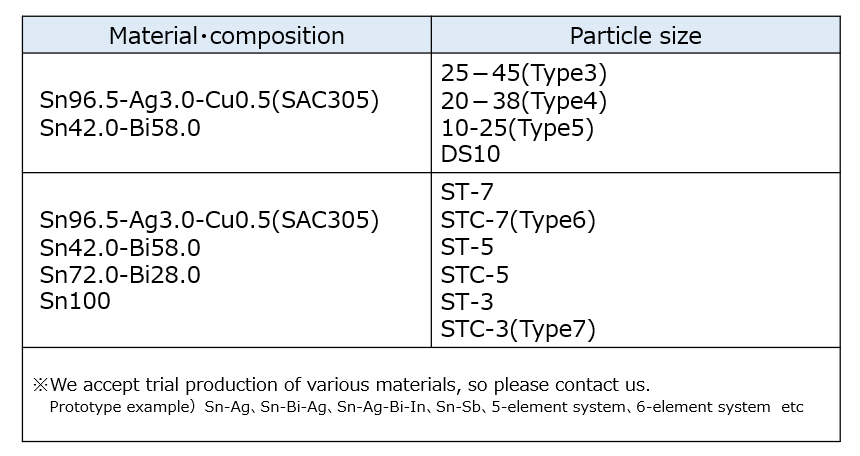

- Utilizing our own designed high-pressure atomized process, we could offer

fine powders. Especially, K series is fine powder with high sphericity

and sharp particle size as compared with conventional items.

- Applications

(1) Thick film conductive paste (sintering /polymer type)

(2) Electrode material for LTCC / MLCC

(3) Through-hole paste

(4) Conductive adhesive

- Features

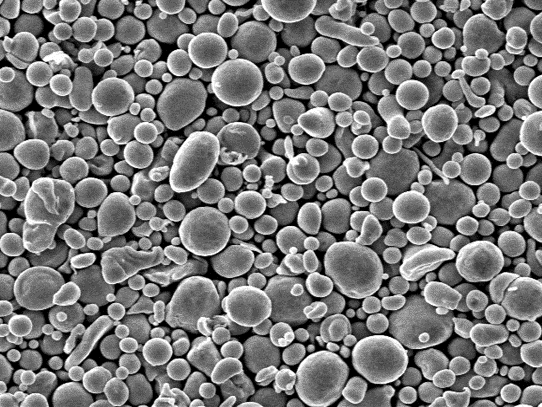

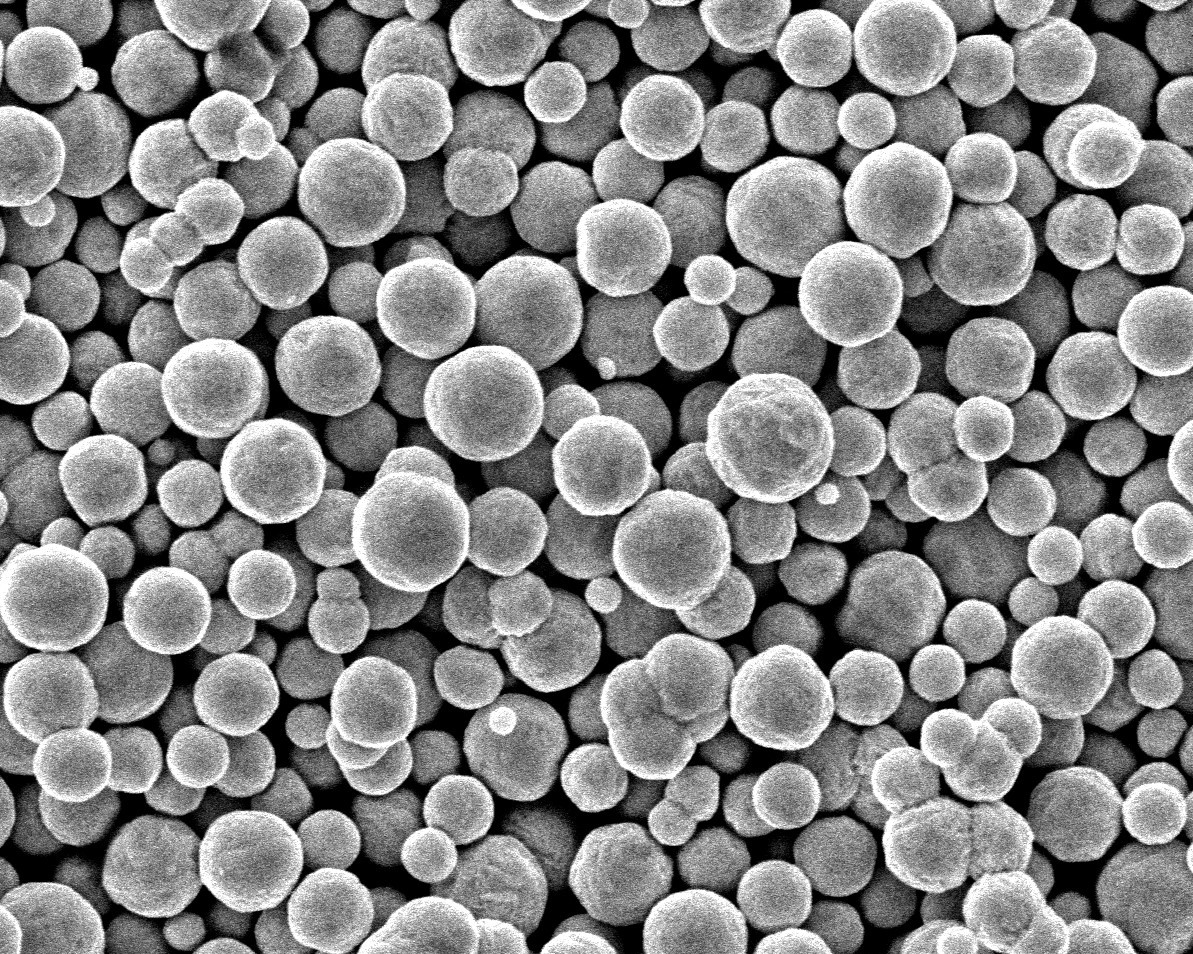

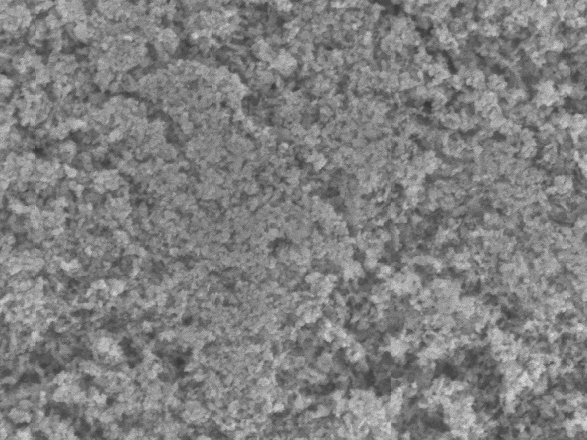

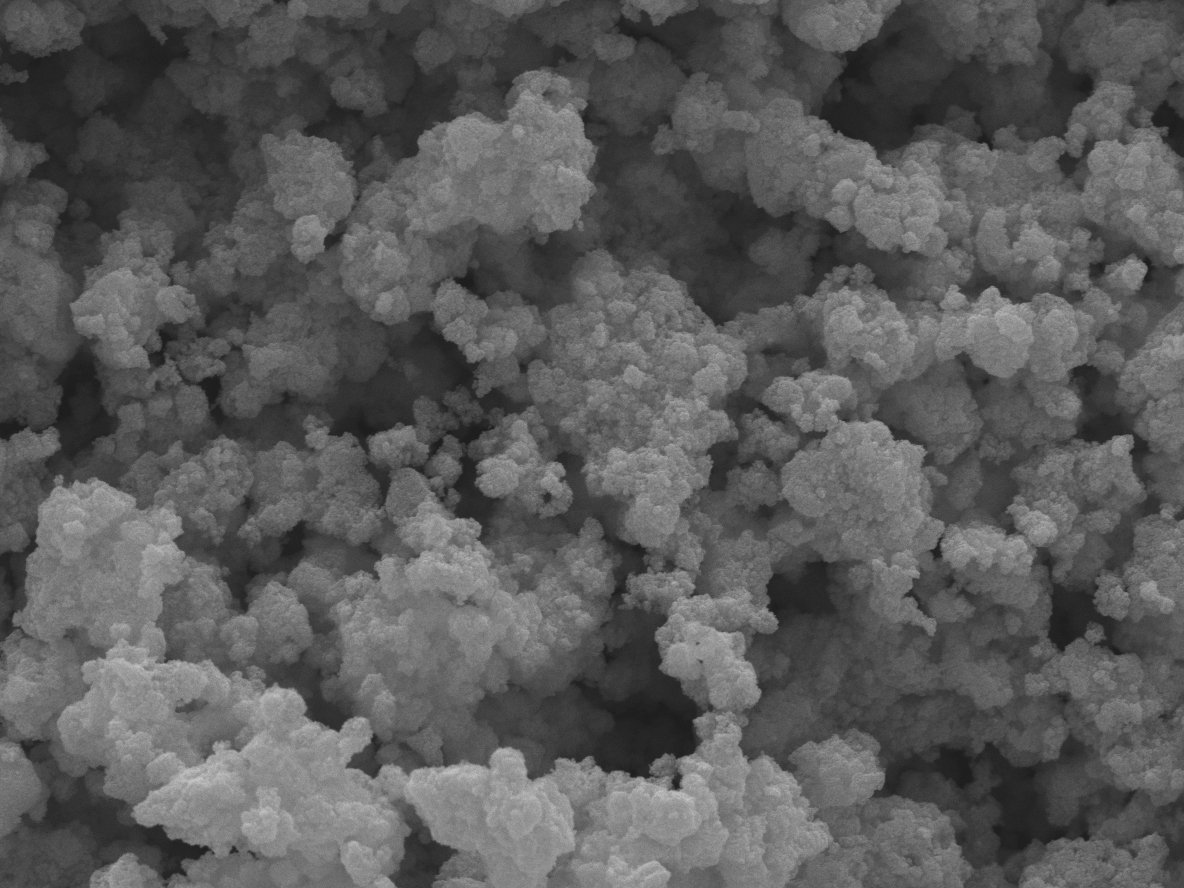

- Utilizing our own wet process, we could offer fine powders with high dispersion,

high packing property and sharp size distribution.

- Applications

(1) Thick film conductive paste (sintering /polymer type)

(2) Electrode material for LTCC / MLCC

(3) Through-hole paste

(4) Conductive adhesive

- Features

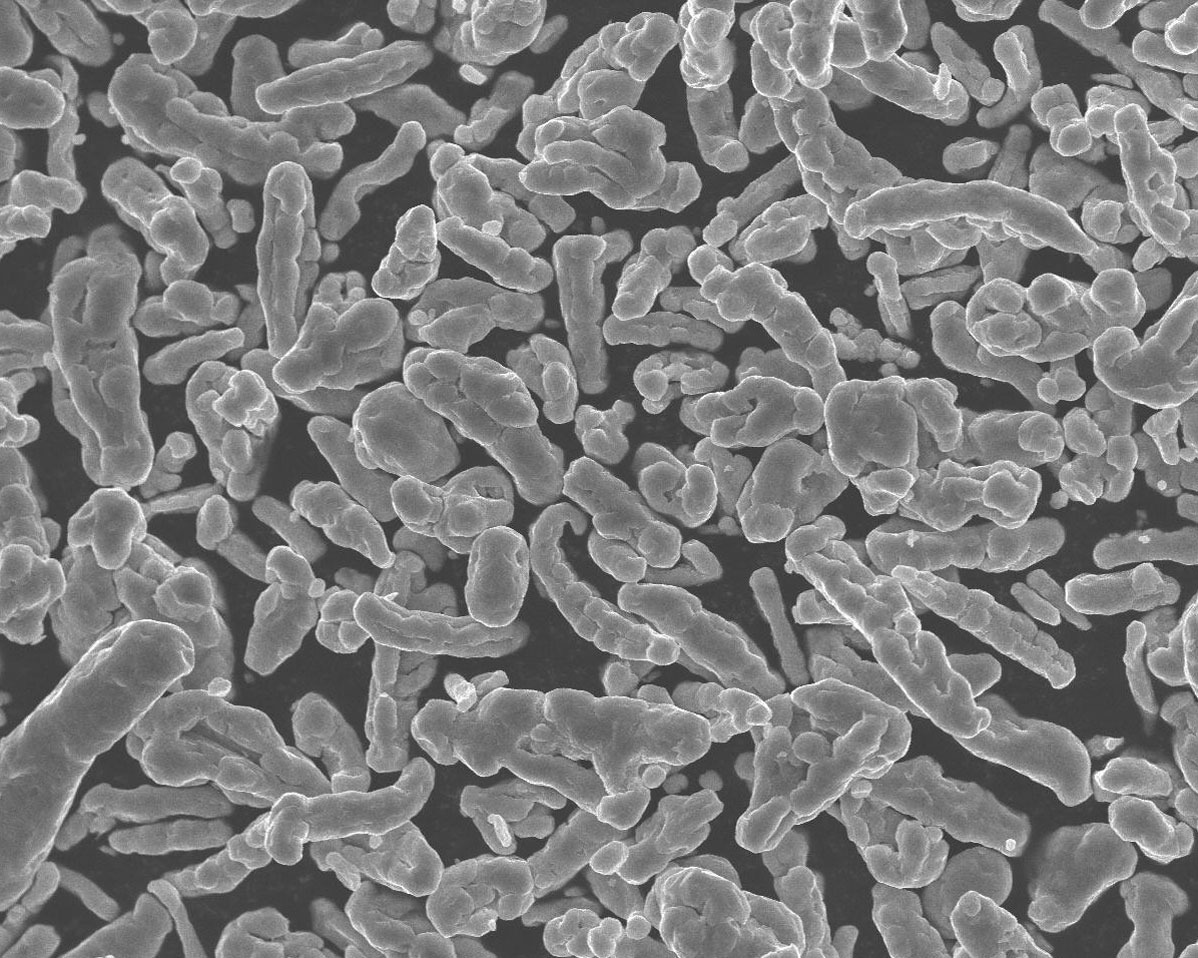

- Using advansed technology and accumulated know-how, we developed high performance Ag coated Cu powders. We could offer powders that meet the required properties such as dispersity, shape and conductivity

- Depending on the purpose, particle size, shape, coat ratio can be selected.

In addition, we could also coat other than silver..

- Features

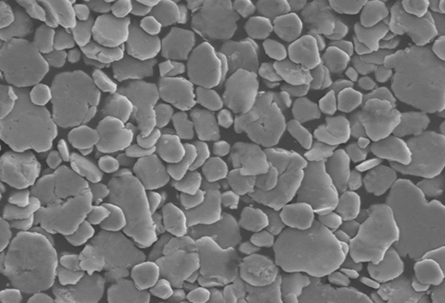

- We could offer a wide variety of flake/plate shaped powders using our wet

and atomized powders. We could adjust thickness and particle that powders.

- Applications

(1) Thick film conductive paste (sintering /polymer type)

(2) Electrode material for LTCC / MLCC

(3) Through-hole paste

(4) Conductive adhesive

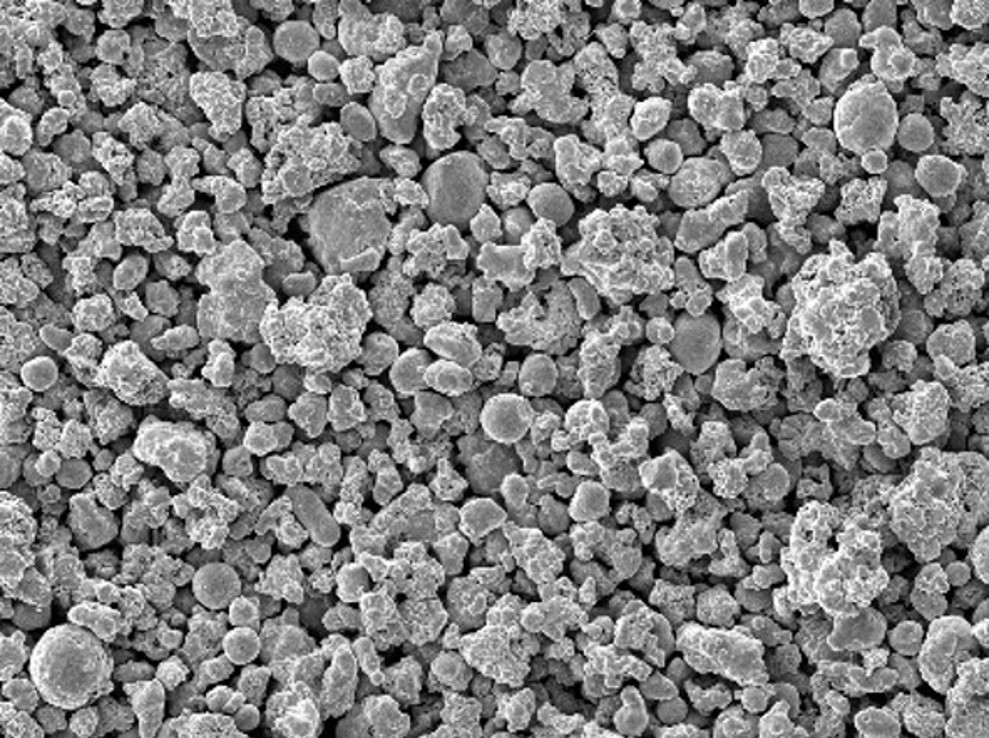

- Features

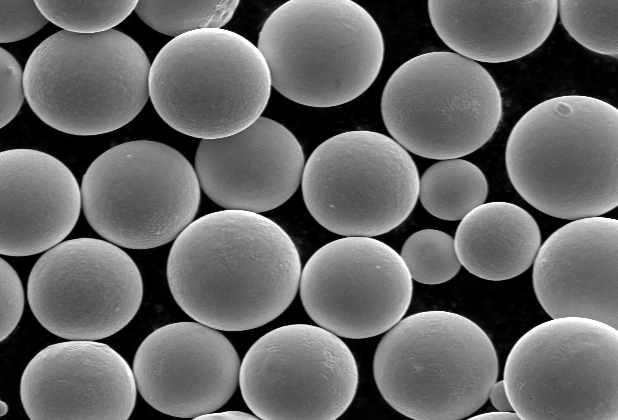

- Utilizing our own pulverization process, we could offer powders with high

packing property.

- Applications

(1) Through-hole paste

(2) Thick film conductive paste (sintering /polymer type)

(3) Electrode material for LTCC / MLCC

(4) EMI shield

(5) Conductive adhesive

-

This is a relatively large-diameter copper powder manufactured using our own atomization technology.

- Features

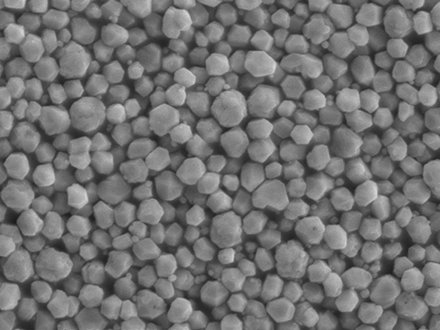

- Features

- Utilizing our own wet process, we could offer the powder with high dispersion,

high filling, and sharp size distribution.

- Applications

(1) Thick film conductive paste (sintering /polymer type)

(2) Inductors,Electrode material for LTCC

(3) Electrode materials for Touch panel

(4) Conductive adhesive