Product Information

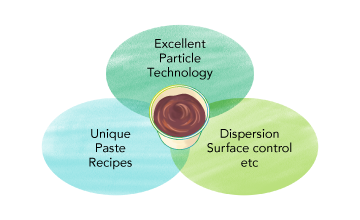

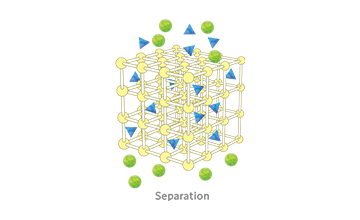

We have developed a copper sinter paste as a bonding material for next generation power semiconductors. This product is expected to be a reliable, heat resistant, and environmentally friendly (lead free) material for high output, reliable power devices used in EV, electricity generating/distributing devices, industrial devices, etc. Our product range features products optimized through our original material design for both pressure bonding and non-pressure bonding manufacturing processes.

Recent Activities

Exhibition/Conference List

| Year | Exhibition/Conference | Title |

|---|---|---|

| 2018 | TMS2018 | Low Temperature Bonding Material with Submicron Copper Particles |

| PCIM Europe2018 | Sintering Cu paste die-attach for high TJ power devices | |

| 3D-PEIM2018 | New bonding Cu ink by using low temperature sinterable Cu particles | |

| IMPACT2018 | Development of high performance synchronous rectifier module by multi-chip Cu sintering technology | |

| 2019 | PCIM Europe2019 | The characteristics of Sintered Copper Layer by Pressure Sintering Process for Power Module Application |

| ECTC2019 | The properties of Cu sinter paste for pressure sintering at low temperature | |

| ISAPP2019 | Reliabilities of Cu sinter paste for pressure sintering at low temperature | |

| 2020 | Mate2020 | Joining Properties of Cu Sinter Material by Pressure Sintering Process |

| PCIM Europe2020 | Bonding with copper paste for pressure sintering process | |

| ECTC2020 | The bonding properties of various surface finishes with Cu paste for pressure sintering | |

| 2021 | PCIM Europe2021 | Bonding Properties of Cu Sinter Paste for Pressureless Sintering Process |

| 2022 | ECTC2022 | Bonding Properties of Cu Paste in Low Temperature Pressureless Processes |

| PCIM Europe2022 | Bonding Properties and Reliability Evaluation of Cu Paste in Low Temperature Pressureless Sintering | |

| 2023 | ICEP2023 | Reliability Evaluation of SiC/Cu Substrate Die-attached Modules with Sintered Cu Joint and Pb-free Solder |

| PCIM Europe2023 |

Bonding Properties and Reliability Evaluation of Cu Sinter Paste for Pressure SinteringMore

|

CVC

Corporate Venture Capital

We pursue co-creation of new businesses

through collaboration with startups.

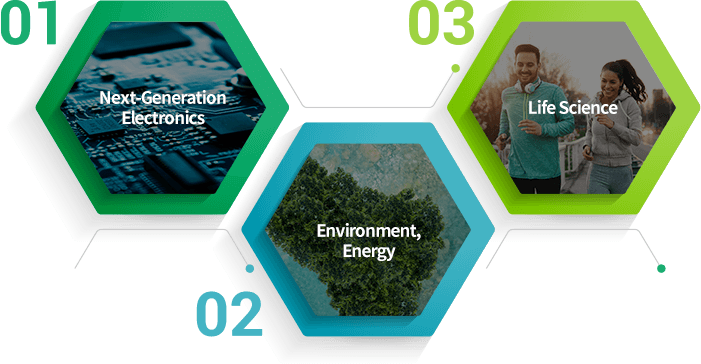

Business Fields of Focus

STORIES

New Materials

DOWNLOAD

Download a Document

Click category to download